EV Components

EV Components

Electric Vehicle (EV) technology demands components that are safe, efficient, and capable of performing under extreme conditions.

Our advanced EV Components Testing facility ensures every part meets BIS, AIS, IEC, ISO, and global automotive standards. With precision testing equipment and expert engineers,

We help manufacturers validate performance, safety, durability, and compliance—ensuring reliable EV solutions for the future of mobility.

EV Batteries

EV batteries are the heart of the vehicle, and their safety is critical.

We conduct:

Charge–discharge cycle testing

Thermal runaway & overheating analysis

Short-circuit protection

Vibration & shock testing

IP protection rating

Life cycle & endurance assessment

Overcharge / over-discharge testing

These tests ensure long life, stable performance, and zero safety risks.

Battery Management Systems (BMS)

The BMS controls battery health, performance, and safety.

Our testing verifies:

Cell balancing accuracy

Voltage & current monitoring

Thermal control performance

Communication reliability

Fault detection systems

This ensures the battery operates safely in all driving conditions.

EV Chargers (AC & DC Fast Chargers)

We evaluate home chargers, commercial chargers, and fast-charging stations.

Testing includes:

Output efficiency

Overload and surge protection

Communication interface reliability (OCPP, CAN, etc.)

Thermal stability

EMI/EMC compliance

This ensures safe and efficient charging for all EV types.

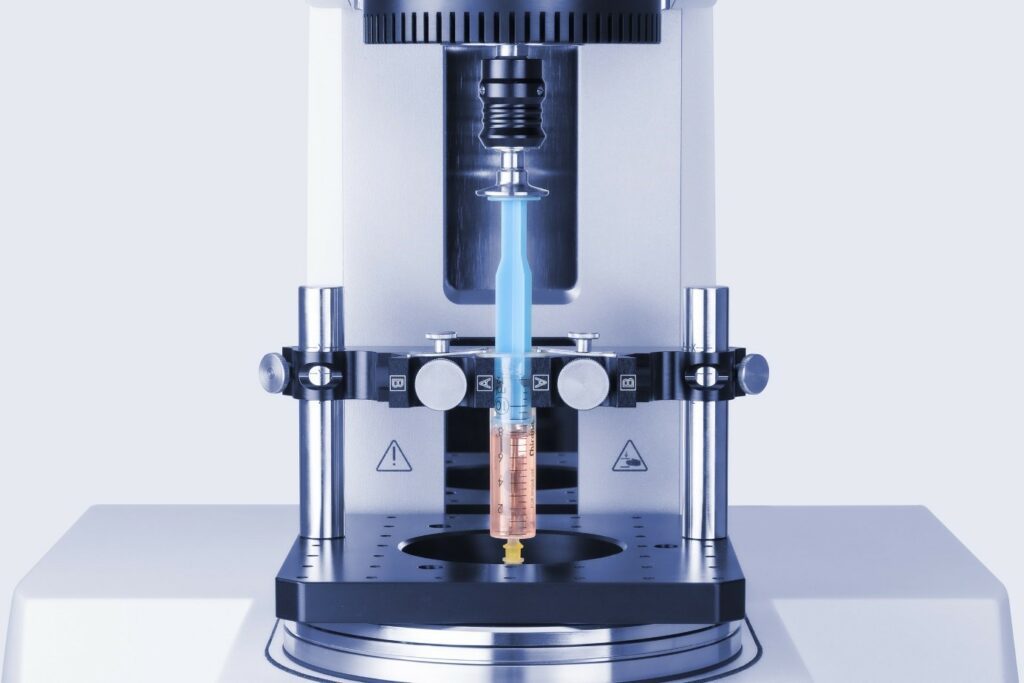

Motor Controllers & Inverters

Motor controllers regulate power delivery to the EV motor.

Our testing includes:

Efficiency measurement

Switching performance

Thermal resistance

Fault tolerance

Load handling capability

Ensuring smooth, efficient, and safe vehicle operation.

Electric Motors

High-performance motors are essential for EV acceleration and efficiency.

We test:

Torque and speed performance

Vibration & noise levels

Heat generation

Energy efficiency

Durability under load

This ensures motors operate reliably in all terrains and climates.

DC-DC Converters

Converters stabilize power for electronic systems.

Our testing checks:

Voltage regulation accuracy

Short-circuit behavior

Efficiency & thermal performance

Ripple and noise levels

Ensuring consistent performance across all operating conditions.

Charging Cables & Connectors

We test connectors for:

Electrical safety

Heat resistance

Mechanical strength

Waterproofing (IP rating)

Durability & wear resistance

Ensuring safe and reliable charging every time.

Why EV Components Testing Is Important

Testing ensures that EV components:

Meet mandatory BIS, AIS, ISO, and IEC standards

Operate safely without overheating or electrical failure

Deliver long-term durability and high performance

Reduce risks of fire, malfunction, or breakdown

Ensure reliability for both commercial and personal EVs

Improve user safety and vehicle efficiency

PRODUCTS

- Wiring Harness

- Battery

- EV Charger

- Acceleration Pedal

- Module

- Break Pedal

- Mobile Charger used in Vehicle

- Tracking Device

- GPS Module used in Vehicle

STANDARDS

- IEC 60068

- IEC 62620

- IEC 62660

- IS 16893

- ISO 16750

- ISO 6469

- GB 38031

- SAE J2464

- ISO 20653

- IEC EN IEC 61851-21

- IS 17017-21

TESTS

- EMI -EMC Test

- Immunity Test

- Hight Temperature and Low Temperature Environmental Test

- Air to Air Thermal Shock Test

- Water sealing Test

- Dust Protection Test

- Electrical Performance Test

- Salt Spray Test,

- Solar radiation Test

- Xenon Arc Weathering Test

- UV and Ozone Test

- Temperature Cycling Test

- Liquid to Liquid Thermal Shock Test

- Battery Testing

- Metal and Polymer identification test

Why Choose Us

At Swastik Electronics Testing Centre, we are committed to delivering high-quality, accurate, and reliable testing services that help manufacturers achieve compliance, improve product performance, and ensure safety. Our advanced infrastructure and expert technical team make us a trusted partner for all types of testing requirements.

- Accredited & Reliable Laboratory

- Advanced Testing Infrastructure

- Experienced Technical Team

- Comprehensive Testing Solutions

- Fast & Transparent Reporting