Rubber And Polymer Parts

Rubber And Polymer Parts

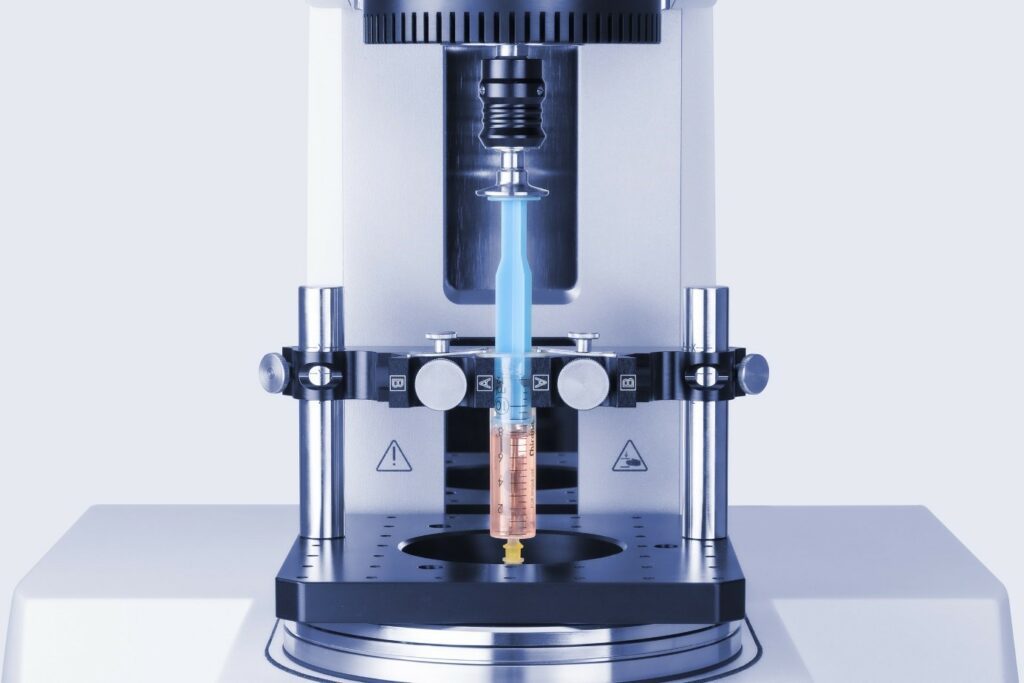

We manufacture and supply premium Rubber and Polymer Parts designed for durability, flexibility, and consistent performance across a wide range of industries. Our components are engineered to withstand extreme temperatures, pressure, chemicals, and demanding operational environments.

Whether you need standard parts or customized solutions, we ensure precision, reliability, and long service life in every product we deliver.

What Are Rubber & Polymer Parts?

Rubber and polymer parts are essential components used in machines, automotive systems, electrical assemblies, industrial equipment, and consumer products. These materials offer excellent resistance, flexibility, insulation, and shock-absorbing properties, making them vital for performance and safety.

We offer components in:

Natural Rubber (NR)

EPDM

Silicone Rubber

Neoprene (CR)

Nitrile Rubber (NBR)

Polyurethane (PU)

PVC, ABS & Other Engineering Polymers

Our Range of Rubber & Polymer Parts

We supply a wide range of components tailored for industrial and commercial applications:

Rubber Components

Rubber Gaskets & Seals

Rubber Bushes & Mounts

O-Rings & Custom Sealing Parts

Rubber Sheets & Profiles

Anti-Vibration Rubber Parts

Rubber Diaphragms & Insulators

Polymer Components

Molded Polymer Parts

Plastic Housings & Enclosures

Polymeric Handles & Caps

Precision-Molded Components

Polymer Connectors & Clips

Custom Injection-Molded Parts

Each component is designed to deliver strength, stability, chemical resistance, and long-term durability.

Why Choose Our Rubber & Polymer Parts?

High Durability & Wear Resistance

Excellent Heat, Oil, and Chemical Resistance

Custom Designs & Precision Manufacturing

Cost-Effective Solutions for All Industries

Compliance With Global Quality Standards

Fast Production, Quality Control & Timely Delivery

Our advanced molding and fabrication processes ensure consistent quality and dependable performance.

Industries We Serve

Our rubber and polymer components are widely used in:

Automotive & Electric Vehicles (EVs)

Industrial Machinery & Equipment

Electrical & Electronic Systems

Aerospace & Defense

Renewable Energy & Solar Equipment

Medical & Healthcare Devices

Consumer Products & Appliances

We provide both standard and custom-engineered parts to meet specific project requirements.

Applications of Rubber & Polymer Parts

Sealing & insulation

Shock absorption & vibration control

Protection against dust, moisture & contaminants

Electrical insulation & cushioning

Structural support for mechanical assemblies

Chemical-resistant parts for industrial systems

PRODUCTS

- Sensors

- Motors

- Batteries

- Chargers

- Infotainment System

- Logger

- Horn

- Spark Plugs

- Music system

- Interactive Dashboard

- Car Antenna

STANDARDS

- ASTM G 154

- ISO4892-3

- IEC 60068-2-1

- IS 9000

- ASO D 001

- IEC 60068-2-30

- IEC 60068-2-78

- ASTM B117

- DIN 50021

- IS 5528

- ISO-10289

- ISO-9227

- JISZ2371

- IEC-60068-2-14

- SAE J1455

- IS D 1601

- IEC 60068-2-6

- IEC 61373

- IEC-60068-2-27

- IEC-60068-2-64

- ISO 16750

- SAE J1211

- ISO 10605

- JSS 55555:2012

- JIS D 1601

- JIS D 5500

- MIL 810 – H

- MIL810 G

- JASO D 001

- QM 333

- JSS 50101

TESTS

- Humidity Chamber Test

- Hot And Cold Conditioning Test

- Thermal Shock

- Cyclic Environmental Corrosion

- Dust And Water (Ingress Protection)

- Xenon Arc Weathering Test

- UV Resistance

- Leakage current

- Current Cycle

- High Voltage

- Temperature Rise

- Voltage Drop Test

- Vibration test

- 1.5Ton and 6 Ton Shaker

- VRC Controller

- With environmental

chamber - Durability Bench Test

- Pneumatic Life cycle

- Mechanical Strength

- Vibration test

- 1.5Ton and 6 Ton Shaker

- VRC Controller

- With environmental

chamber - Durability Bench Test

- Pneumatic Life cycle

- Mechanical Strength

Why Choose Us

At Swastik Electronics Testing Centre, we are committed to delivering high-quality, accurate, and reliable testing services that help manufacturers achieve compliance, improve product performance, and ensure safety. Our advanced infrastructure and expert technical team make us a trusted partner for all types of testing requirements.

- Accredited & Reliable Laboratory

- Advanced Testing Infrastructure

- Experienced Technical Team

- Comprehensive Testing Solutions

- Fast & Transparent Reporting